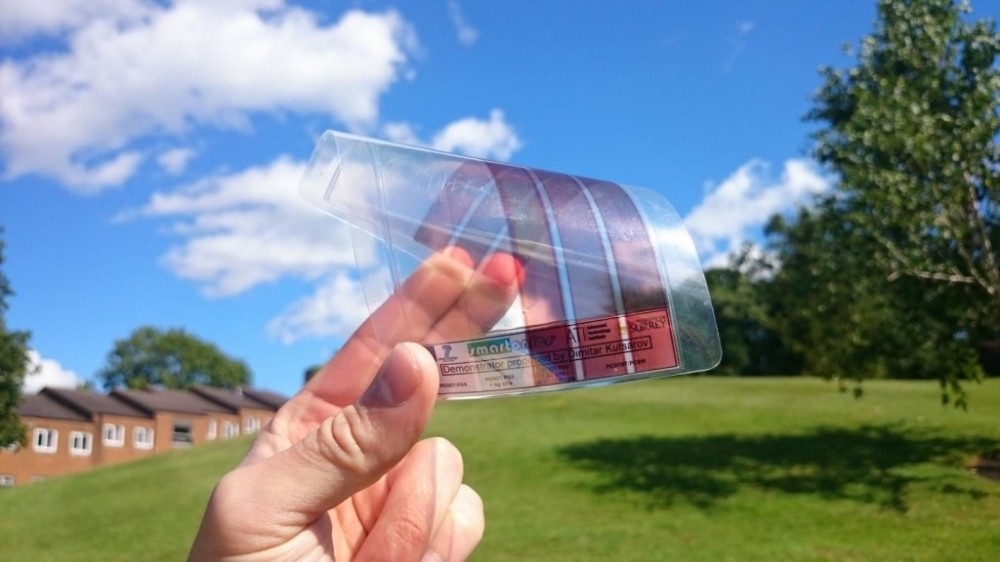

Scientists at the Advanced Technology Institute (ATI) in the University of Surrey have created a one-atom-thick flexible graphene sheet that can generate electricity from the heat and light it absorbs.

The team produced the sheet using a technique called nanotexturing. As the name suggests, the process involves building nano-sized graphene around a textured metallic surface.

In deciding what architecture to use in the construction, the team had to look to nature. They gained inspiration from the unique structure of the eyes of moths.

The reason according to Professor Ravi Silva, head of ATI, is that the eyes of moths possess microscopic patterning that offers them the remarkable ability to see in very low-light conditions.

This property of the moths’ eye structure is vital because it addresses a limitation of graphene. While scientists tout graphene as a super-conductor of electricity and possessing super-strength, its light absorption ability is far from impressive. A standard graphene sheet absorbs 2-3% of the light that falls on it.

After the ATI team patterned the graphene sheet based on the moths’ eye structure, the absorbency of the sheet increased by 90%. The sheet is thus the material with the highest light absorbency for its weight ever created.

While the technology is still in its infancy, the team has already uncovered a number of future applications for the technology. First off, the sheets may be embedded in windowpanes and wallpapers. When installed in a home, they would absorb waste light and heat from both inside and outside the home to generate electricity.

Alternatively, a number of devices could be coated in these sheets with the desirable effect of such devices being constantly recharged and the convenience of not having to connect the devices to the mains.

Looking forward, the team’s next step is to begin incorporating their material in different existing technologies.